The modern automotive industry is evolving rapidly, and the vehicle interior has become one of its key areas of innovation. Comfort, aesthetics, and functionality of the passenger cabin are now just as important as engine performance or aerodynamics. Today’s passenger cars and electric vehicles are designed with the user in mind, where every detail – from the dashboard to ambient lighting – shapes the driving experience.

In this context, IPT adhesive tapes are an essential construction solution. They enable precise, durable, and visually clean bonding of components without the need for screws, rivets, or liquid adhesives. Self-adhesive technology reduces assembly time, lowers vehicle weight, and enhances both acoustic and thermal comfort inside the cabin.

Advanced Materials and Functional Adhesive Technologies

The vehicle interior is a space where numerous materials meet – from ABS, PC, PP, and PVC plastics to aluminum, glass, fabrics, and composites. This diversity requires advanced bonding technologies that guarantee high adhesion, durability, and aesthetic integration.

Acrylic tapes from IPT provide strong and flexible connections resistant to temperature changes and UV exposure. Transfer tapes allow thin, precise bonding where every millimeter counts – such as in displays, sensors, or decorative trims. Foam tapes, on the other hand, offer both bonding and vibration damping, improving overall acoustic comfort.

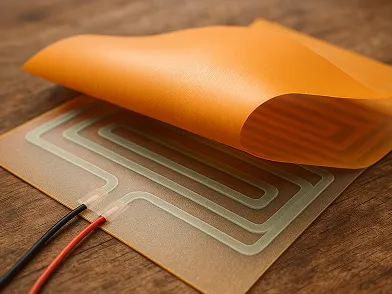

In applications requiring heat dissipation, TM (Thermal Management) materials – including thermally conductive and electrically insulating tapes – ensure efficient heat transfer from electronic components such as LED modules, sensors, and screens, preventing overheating and extending system reliability.

Applications in Automotive Interior Design

IPT adhesive tapes are used throughout nearly every area of the vehicle cabin:

- Cockpit and center console – for mounting touchscreens, control panels, sensors, and decorative trims. Transfer tapes create clean, invisible joints, while acrylic tapes ensure strong adhesion to painted or plastic surfaces.

- Doors and side panels – for bonding upholstery, LED lighting, and decorative profiles. Foam tapes compensate for thermal expansion and dampen vibrations caused by driving dynamics.

- Headliner and upper interior zones – for attaching wiring harnesses, microphones, sensors, and ambient lighting modules. TM tapes dissipate heat from LED systems, and transfer tapes provide clean, fast installation.

- Seats and seating components – for fixing heating mats, occupancy sensors, and upholstery. TM tapes stabilize heating performance, while foam tapes increase vibration and compression resistance.

- Decorative elements and ambient lighting – for securely and invisibly attaching trims made of wood, aluminum, or plastic. Thermally conductive TM tapes protect LED systems from overheating and extend their lifespan.

- HVAC systems – for sealing ventilation ducts and securing insulation panels. Specialized moisture-resistant tapes ensure system durability under varying pressure and humidity conditions.

Advantages of Using IPT Adhesive Technology

Using adhesive tapes in the automotive sector is not just an alternative to mechanical assembly – it represents a new standard in vehicle manufacturing. Implementing IPT adhesive solutions brings measurable benefits:

- Reduced vehicle weight by eliminating mechanical fasteners.

- Shorter assembly times and simplified production processes.

- Improved aesthetics – invisible joints and precise component alignment.

- Increased connection durability and resistance to vibrations, moisture, and temperature.

- Enhanced acoustic and thermal comfort within the cabin.

The Future of Interior Bonding Technology

IPT’s self-adhesive technology is a cornerstone of modern automotive design. With acrylic, foam, transfer, and TM tapes, vehicle manufacturers can design interiors that are quiet, lightweight, durable, and environmentally friendly.

In the era of electromobility and digital interfaces, adhesive tapes are no longer just connectors – they have become integral structural components, supporting design, ergonomics, and reliability across every segment of the vehicle interior.