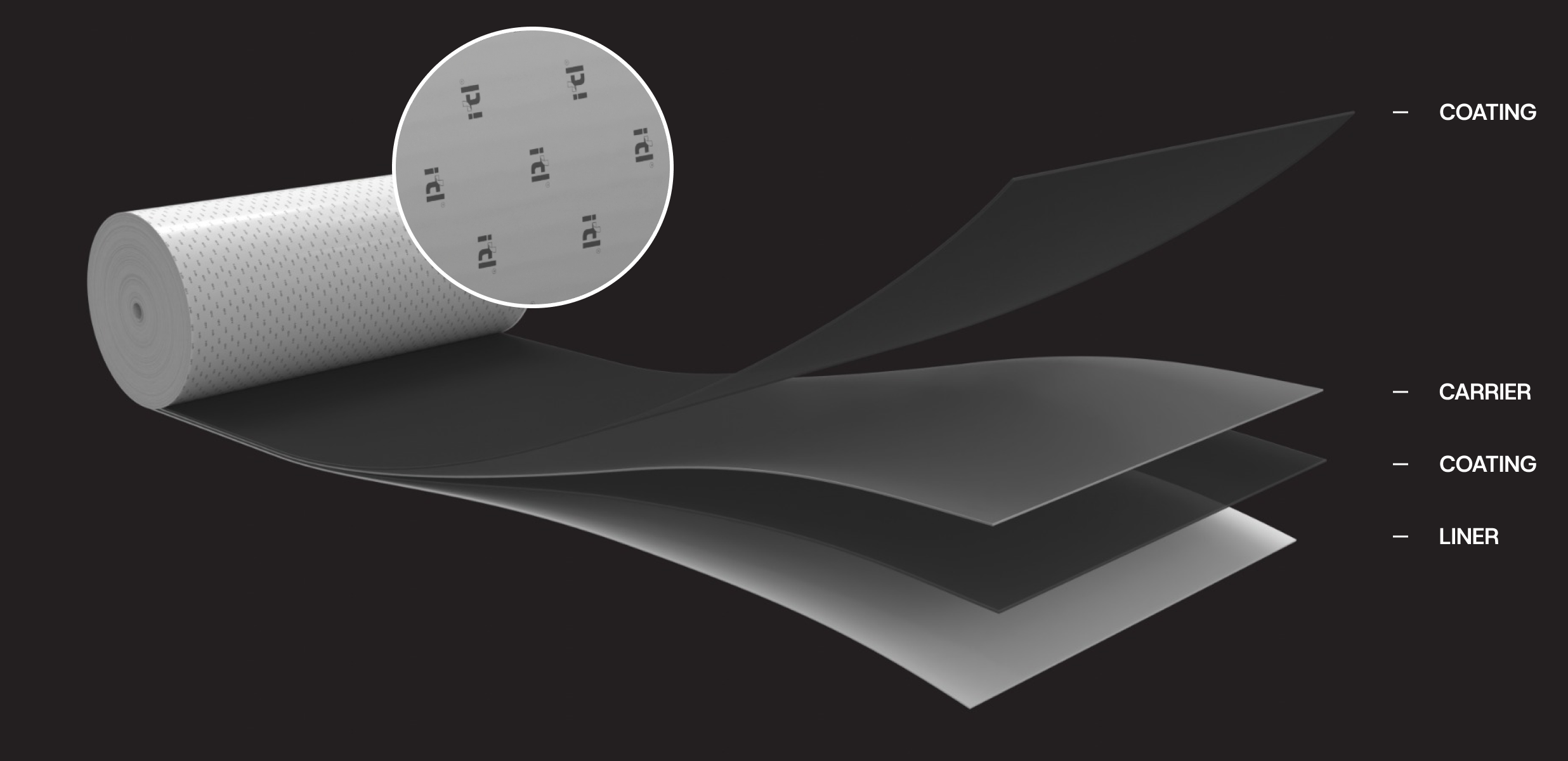

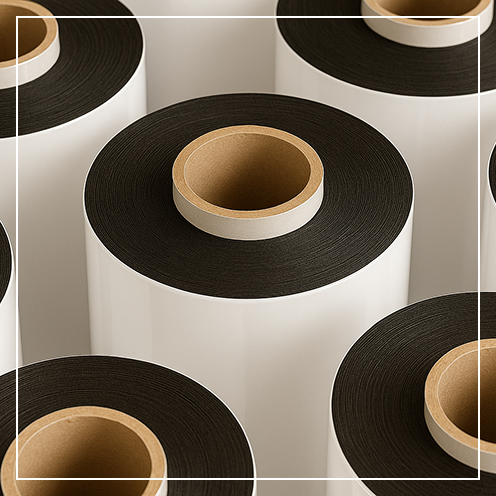

IPT™ acrylic foam tapes are advanced structural tapes that combine high strength with flexibility and clean aesthetics. With outstanding resistance to UV, moisture, chemicals, and a wide temperature range, they perform reliably even in the most demanding conditions. Designed and tested in our state-of-the-art R&D department, they are based on proprietary formulations and technologies, ensuring maximum reliability and top performance in industrial applications.

Strength & Durability

Our acrylic tapes provide stable and long-lasting bonds even under the most demanding industrial conditions. With proven resistance to environmental factors, they ensure reliability and safe assembly for years.

Stress Compensation

The foamed acrylic structure enables flexible load transfer and reduces the risk of fatigue failures. The tapes absorb vibrations, compensate for thermal expansion differences, and enhance the aesthetics of the joint.

Advanced R&D

Each IPT™ tape is developed in our modern R&D department, based on proprietary adhesive formulations. This guarantees consistent quality, customization options, and reliability in critical industrial applications.

An economical and proven solution for standard industrial applications, offering a good balance of cost and performance. G3 tapes ensure stable bonding in typical assembly conditions and provide versatile use across industries.

An advanced generation of acrylic tapes designed for the most demanding industrial applications. G4 is characterized by enhanced mechanical strength, superior adhesion to low-energy surfaces, and extreme environmental resistance.

The new generation of IPT™ tapes under development by our R&D department, combining the latest acrylic technologies with even greater durability and performance. G5 is designed to meet the future needs of industry, delivering improved parameters and new application opportunities.

FAQ

Generation G3 is a universal solution for standard industrial applications, offering reliable bonding and good environmental resistance. Generation G4 represents advanced tapes – with higher bonding strength, extreme weather resistance, and excellent joint aesthetics.

Standard acrylic tapes maintain their properties between -30°C and +120°C, while special formulations can withstand up to +180°C. The operating range depends on the adhesive system – for example, UV-HMPSA allows for faster applications and higher thermal resistance.

Yes, thanks to their dimensional stability and resistance to deformation, acrylic tapes perform well in converting processes. Their structure ensures cutting precision and compatibility with automated assembly lines.

Standard acrylic tapes work better on HSE surfaces (metal, glass), but special formulations with adhesion-modifying additives improve bonding on difficult LSE substrates, such as plastics.

Thanks to their structure and flexibility, acrylic tapes absorb stresses caused by differences in thermal expansion, preventing delamination and loss of adhesion. This makes them particularly useful in applications combining different materials, e.g., glass–metal or plastic–aluminum.

Acrylic tapes provide high adhesion to a wide range of substrates – including metals (stainless steel, aluminum), glass, plastics (ABS, PMMA, PP, PC, EPDM), and composites. This makes them suitable for construction, automotive, electronics, and many other industries.

These tapes maintain performance in extreme conditions – from -40°C to +150°C – and are resistant to UV radiation, moisture, chemicals, and aging. Their closed-cell structure prevents water penetration and ensures long-lasting bond durability.

See also

Acrylic tapes are among the most advanced and versatile adhesive tape solutions used across modern industries. Thanks to innovative acrylic formulations – including water-based, solvent-based, and UV-HMPSA technologies – they offer exceptional durability, aging resistance, and stable performance under varying environmental conditions. They are indispensable wherever strong, long-lasting bonding and material longevity are essential.

In industrial applications, acrylic tapes are widely used in automotive, electronics, household appliances (white goods), construction, and advertising sectors. They provide reliable structural bonding, stress compensation, and eliminate the need for visible fasteners, enhancing both the appearance and functionality of the final product. Available in multiple thicknesses and configurations, they can be precisely tailored to specific process and application requirements.

At IPT, we design and manufacture high-performance acrylic tapes for demanding industrial applications. Our products ensure consistent quality, excellent mechanical strength, and long-term stability. By combining innovative adhesive technology with extensive application expertise, we deliver solutions that meet the needs of both converters and end manufacturers.

If you’re looking for reliable double-sided acrylic tapes for industrial bonding, IPT provides top-quality products and full technical support to help you achieve lasting and efficient results.

Siemiradzkiego 46 str.

05 -080 Izabelin, Poland

TAX ID: 7343550873