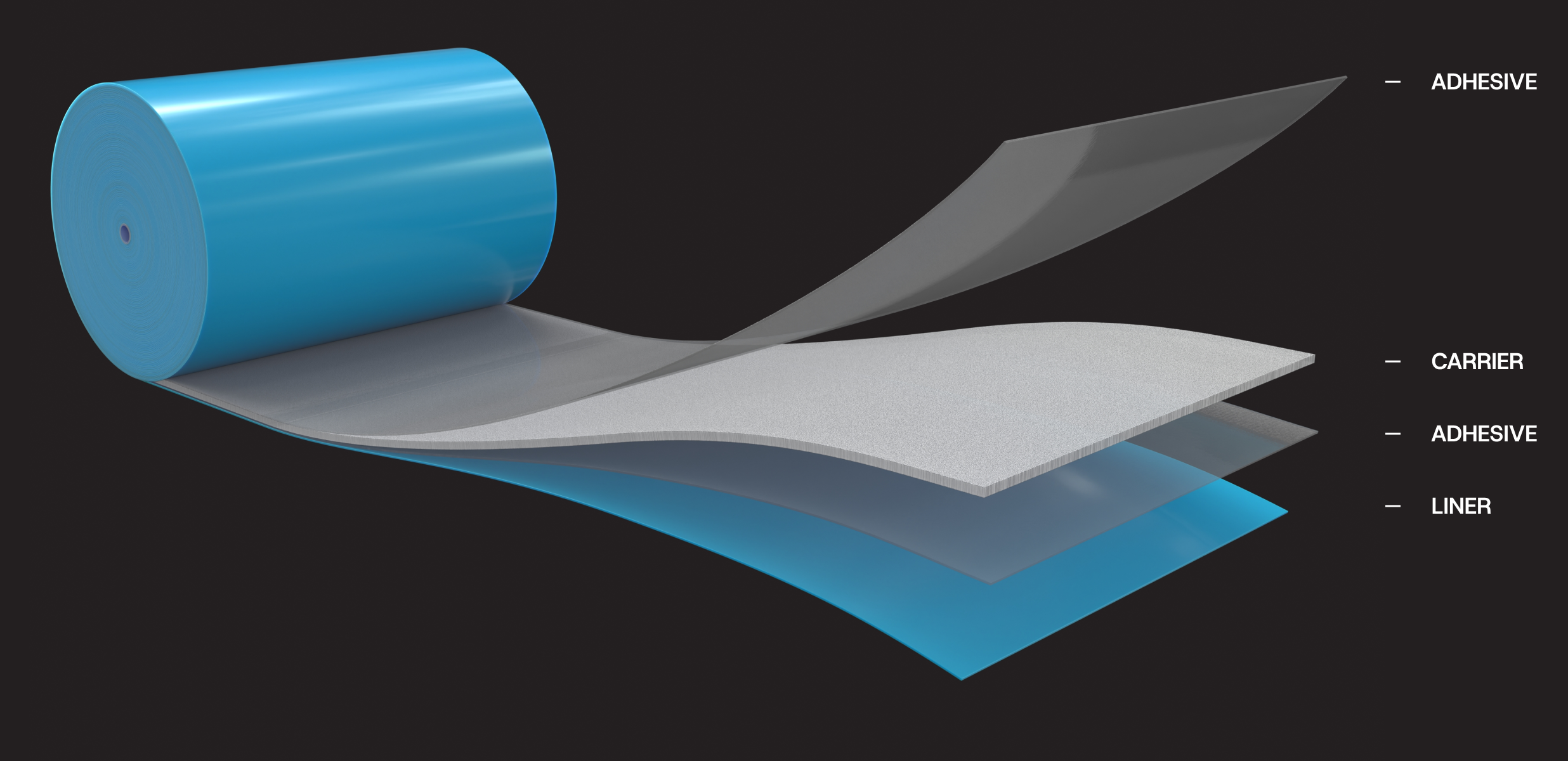

Their structure ensures an even distribution of forces at the bonding site while maintaining resistance to external factors such as moisture and temperature fluctuations. This makes them a reliable solution wherever stability and long-term performance are essential.

Compensation and Adaptation

Foam tapes perfectly adjust to rough, curved, and irregular surfaces, ensuring stable and uniform bonding.

Cushioning and Damping

Thanks to their foam structure, the tapes effectively absorb vibrations and reduce noise, enhancing the durability and operating comfort of devices and structures.

Polyethylene foam features a closed-cell structure that provides low water absorption and high chemical resistance. It is lightweight, rigid, and performs well in applications requiring dimensional stability.

Polyurethane foam is an open-cell material distinguished by its high flexibility and energy absorption capacity. It is ideal for applications requiring vibration damping and acoustic performance.

FAQ

The key parameters are foam density and hardness, carrier thickness, and adhesive type. These factors affect the tape’s ability to compensate for irregularities, damp vibrations, and resist shear forces.

Yes, properly selected foam tapes with acrylic or acrylic foam adhesive systems offer high resistance to UV radiation, moisture, and temperature fluctuations, making them ideal for outdoor use.

Thanks to their porous structure, they absorb mechanical energy, damp vibrations, and limit noise transmission, which increases equipment lifespan and improves working comfort.

Thickness should be matched to assembly tolerances and the unevenness of bonded surfaces. Thicker tapes better compensate for larger gaps, while thinner ones ensure greater stability and lower susceptibility to deformation.

Thanks to their flexible structure and ability to fill gaps, foam tapes provide durable and aesthetic bonds, even on rough or curved surfaces. They are widely used as double-sided mounting tapes, enabling quick and clean assembly without the need for screws, rivets, or liquid adhesives.

Industrial foam tapes also effectively dampen vibrations and reduce noise, which increases equipment lifespan and enhances user comfort. For this reason, they are commonly used in industries such as automotive, appliances, electronics, and construction, where reliability and resistance to demanding conditions are essential.

With a wide range of thicknesses, foam types, and adhesive properties, foam tapes for sealing and vibration damping can be precisely matched to specific applications. They provide not only durable bonding but also protection against moisture, dust, and mechanical damage. This makes them one of the most versatile mounting solutions in modern industry.

Siemiradzkiego 46 str.

05 -080 Izabelin, Poland

TAX ID: 7343550873