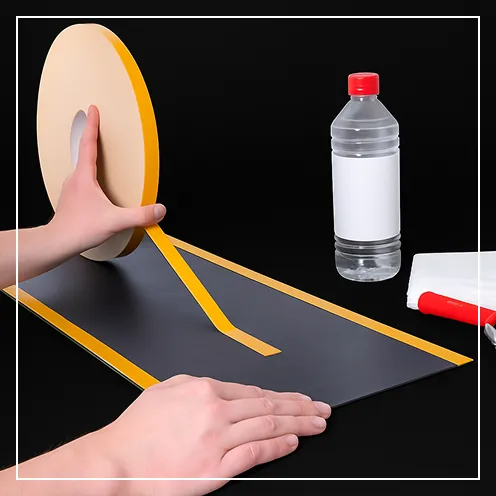

Cleaners and primers are key elements in the bonding process that increase the durability and reliability of adhesive joints. With proper surface preparation, we ensure better adhesion even under challenging application conditions.

Auxiliary bonding chemistry, such as cleaners and primers, is a crucial stage in surface preparation before applying adhesive tapes. Their purpose is to enhance bonding effectiveness by cleaning, activating, or sealing the surface. This enables maximum bond strength even on difficult materials such as low surface energy (LSE) plastics or painted surfaces.

Cleaners are agents used for degreasing and removing contaminants – they not only improve bonding conditions but also minimize the risk of tape delamination. Primers, on the other hand, create an additional adhesive layer between the tape and the substrate – increasing adhesion, evening out surface porosity, and improving bond durability.

These products are used across many industries – from automotive and electronics to home appliances, construction, and advertising. Wherever repeatable, strong, and long-lasting bonds are required, auxiliary chemistry becomes an essential part of the assembly process. It solves problems such as tape delamination, insufficient adhesion, instability in humid environments, and challenging surface conditions.

Cleaner

IPT™ Cleaner removes grease, dust, and contaminants, ensuring a perfectly clean surface ready for tape application.

Primer

IPT™ Primer creates an adhesive layer between the tape and the substrate, improving adhesion to low surface energy (LSE) materials

FAQ

Cleaner is used to remove dirt, oils, and dust – it’s the first step in surface preparation. Primer is used when additional adhesion is needed for difficult materials such as LSE plastics or powder coatings.

No – our cleaners are safe for most industrial substrates. For delicate materials (e.g. painted surfaces), we recommend testing on a small area first.

Typically 1–2 minutes until the primer evaporates. This may vary slightly depending on ambient temperature and substrate type.

Absolutely – proper surface preparation significantly increases bond strength and resistance to aging, moisture, and temperature.

See also

Siemiradzkiego 46 str.

05 -080 Izabelin, Poland

TAX ID: 7343550873

To ensure the durability and reliability of adhesive joints, proper surface preparation is essential. That’s why industrial surface preparation cleaners and primers for adhesive tapes play such an important role in professional bonding applications. They degrease, activate, and stabilize surfaces, increasing tape adhesion even on difficult low surface energy (LSE) materials.

Using auxiliary bonding chemistry directly translates into the quality and longevity of the bond. Surface cleaning and activation agents are effective on materials such as aluminum, steel, glass, and PP. By applying the right primer for low-energy surfaces, it is possible to significantly improve bond durability even under the most demanding conditions – such as high humidity, temperature changes, or mechanical stress.

With IPT’s application expertise, we offer not only cleaners and primers tailored to specific applications but also technical support in selecting the right bonding chemistry. Our experts will help you choose the optimal products to streamline your bonding process, minimize errors, and increase production efficiency. If you want to enhance the durability of adhesive joints – it all starts with proper surface preparation.

See also