TIM (Thermal Interface Management) materials are specialized products that enhance the reliability and lifespan of devices by ensuring efficient heat dissipation. Thanks to their thermal conductivity and flexibility, they play a key role in protecting electronic and mechanical components from overheating and performance loss.

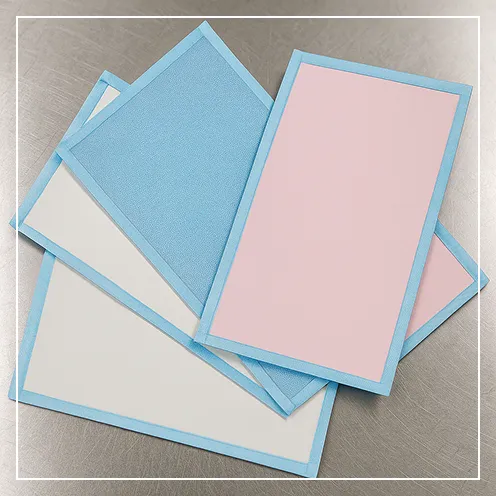

TIM products are characterized by high thermal conductivity, enabling fast and effective removal of excess heat. They are available in various forms – from pads and tapes to pastes and phase-change materials – allowing adaptation to specific applications and assembly processes. Their advantages also include installation flexibility, a compact form suitable for use in miniature constructions, and stability in extreme environmental conditions such as high temperature, humidity, or exposure to chemicals. Additionally, TIM materials provide insulating properties, making them safe to use in high-power devices.

TIM solutions are widely used in key industries where system reliability depends on temperature control. In automotive and e-mobility, they are applied in cooling battery packs and power modules. In consumer and industrial electronics, they ensure the stable performance of processors, sensors, and power supplies. In IT infrastructure and telecommunications, they enable efficient cooling of servers and routers. TIM materials are also applied in modern LED lighting, HVAC systems, energy, and industrial automation – wherever maintaining safe and stable operating parameters is essential.

High Thermal Conductivity

TIM materials are designed to minimize thermal resistance between the heat source (e.g., processor, battery, power module) and the heat sink (radiator, housing). Thanks to their high thermal conductivity, they significantly improve cooling performance, ensuring stable device operation and extending component lifetime.

Flexibility and Reliability in Extreme Conditions

TIM products maintain their properties even under challenging conditions – including high temperatures, humidity, vibrations, or chemical exposure. Available in various forms (pads, tapes, pastes, phase-change materials), they can be easily adapted to specific applications, providing safe and predictable performance in consumer electronics, industrial systems, and electromobility.

Ideal for modern devices with limited space – the thin form of TIM materials allows effective heat management even in miniature constructions.

By reducing thermal losses, TIM products improve the energy balance of devices, supporting sustainable and efficient system operation.

They retain their mechanical and thermal properties over time, ensuring device reliability throughout the entire lifecycle.

FAQ

See also

Thermal interface materials (TIMs) play a crucial role in managing the temperature of electronic components, LED systems, batteries, and power modules in automotive applications. They enable effective heat dissipation from hotspots, ensuring stability, safety, and extended device life. Within its Thermal Interface Management (TIM) portfolio, IPT provides a broad range of solutions: from thermal pads and conductive tapes to greases, pastes, and phase-change materials.

IPT TIM products are designed for demanding applications where traditional cooling methods are insufficient. Our cooling solutions for industry, electronics, and automotive fill gaps between surfaces, improving heat transfer and reducing overheating or component failure risks. With their flexibility, durability, and precise fit, TIMs adapt to different application requirements and environmental conditions.

Through advanced technology and technical support, IPT delivers not only high-performance TIM materials but also the assurance of reliable heat management under all working conditions. Our TIM portfolio ensures efficient, long-term thermal control in high-density energy environments.

Siemiradzkiego 46 str.

05 -080 Izabelin, Poland

TAX ID: 7343550873