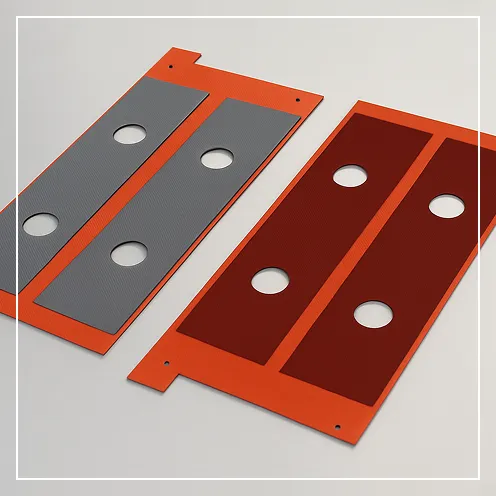

Phase-change materials IPT™ TM are advanced TIM solutions designed to optimize heat transfer between electronic components and cooling elements. Their unique phase transition under heat allows them to change from a solid to a semi-fluid state, perfectly adapting to surface irregularities and ensuring maximum thermal efficiency. Once cooled, they solidify again, creating a durable and clean thermal bond. Ideal for high-power and precision applications, they provide stable, repeatable, and maintenance-free cooling performance that enhances reliability and extends component lifespan.

Active thermal response

Phase-change materials alter their physical state at a specific temperature, automatically adapting to the surface and filling microscopic gaps. This ensures exceptionally efficient and repeatable heat transfer, even in the most demanding applications.

Mechanical and thermal stability

In their solid state, they allow precise positioning and assembly, while after activation they form a uniform thermal connection. Once cooled, they solidify again, providing durability, clean application, and no leakage — key advantages in precision and automated systems.

FAQ

At room temperature, it remains solid for easy handling and assembly. Once the activation temperature is reached, it softens into a semi-fluid state, conforming to surfaces and improving thermal transfer efficiency.

No. These materials are designed for single-use applications. After the phase change and stabilization, reusing them is not recommended to maintain optimal performance.

Typically around 55–60°C, depending on the formulation. The activation point can be adjusted to the application — higher temperatures for high-power components.

No. IPT™ phase-change materials are electrically insulating, making them safe for electronic applications requiring short-circuit protection.

Phase-change materials provide a cleaner application, no leakage, easier automated assembly, and consistent thermal performance — ideal for mass production or precision devices.

See also

Grzegorz Król

Business Development Manager

Siemiradzkiego 46 str.,

05 -080 Izabelin, Poland

TAX ID: 7343550873

IPT™ TM phase-change materials are advanced thermal management solutions designed for efficient heat transfer in demanding and precision applications. Their key feature is temperature-triggered phase transition — from solid to viscoelastic — allowing perfect surface conformity between electronic components and heat sinks.

This property ensures outstanding thermal conductivity and operational stability, even in high-power and high-energy-density systems. They are widely used in cooling microcontrollers, memory modules, power devices (IGBT, MOSFET), telecommunication systems, and precision electronics such as cameras or sensors, where clean application and zero material migration are crucial.

Phase-change materials offer repeatable performance, clean installation, no leakage, and easy integration into automated production lines. They are ideal for manufacturers seeking high thermal efficiency, durability, and full control over application throughout the product’s lifecycle.

See also