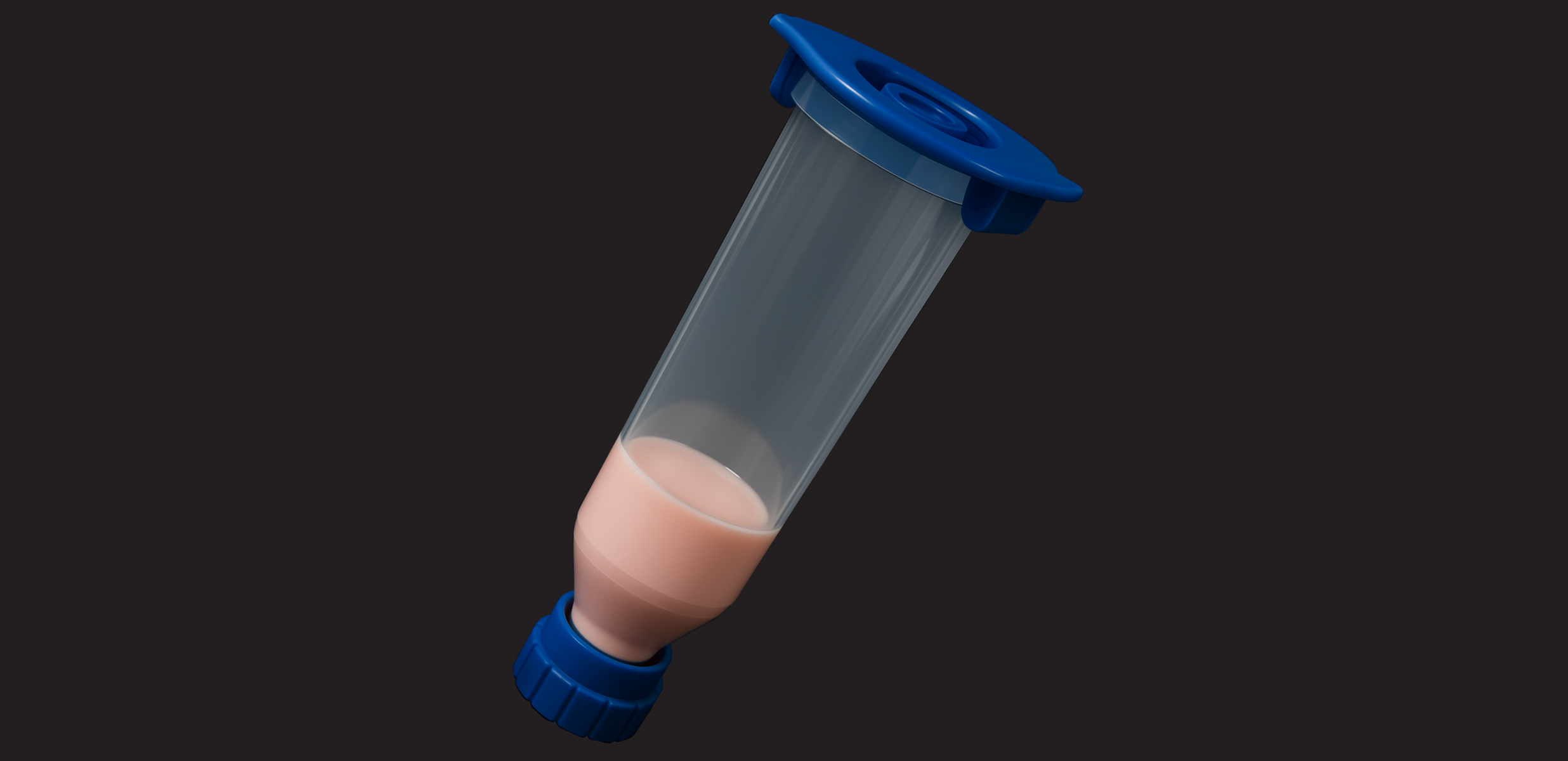

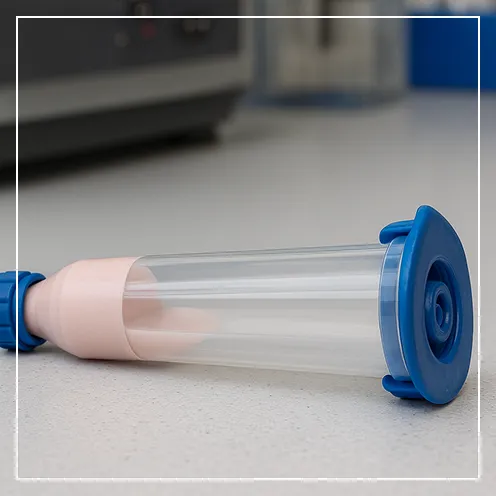

Thermally conductive pastes IPT™ TM are advanced TIM materials that improve heat transfer between electronic components and heat sinks, ensuring efficient thermal management and long-term stability. Their semi-fluid structure perfectly fills microscopic surface gaps, reducing thermal resistance and preventing overheating even under variable loads. Available in silicone and non-silicone formulations, they deliver precise application, high conductivity, and proven reliability in electronics, energy, and telecommunication systems.

Efficient heat transfer in every application

Thermally conductive pastes ensure effective heat transfer between uneven or imperfectly matched surfaces, stabilizing component operating temperatures and preventing overheating. They provide consistent performance even under variable thermal loads.

Technological flexibility and easy application

Available in silicone-based and non-silicone formulations, the pastes can be precisely applied by hand or integrated into automated dispensing systems. Their adaptable consistency allows for accurate dosing and clean processing in both prototyping and mass production.

FAQ

Yes, thermally conductive greases are formulated using silicone oil, which serves as the continuous phase of the compound.

Our greases work effectively in a wide range of temperatures: from –55°C to +200°C, making them suitable for most electronic and industrial applications.

Standard shelf life is 12 months from the production date, provided proper storage conditions are maintained.

Yes, many of our greases can be used with automated dispensing systems. Technical data and application guidelines are available upon request.

No – our greases are electrically non-conductive, ensuring safe use in electronic systems.

See also

Siemiradzkiego 46 str.

05 -080 Izabelin, Poland

TAX ID: 7343550873

IPT™ TM thermally conductive pastes are advanced TIM materials designed to improve heat transfer between electronic components and cooling systems, such as heat sinks. Their consistency and micro-gap filling capability reduce thermal resistance and stabilize operating temperatures of critical components.

The IPT™ TM range includes 1-K and 2-K silicone-based and non-silicone formulations, tailored to the needs of sectors such as consumer electronics, automotive, industry, optoelectronics, and energy storage. Available in various viscosities and thermal parameters, they can be applied manually or through automated dispensing systems.

Using IPT™ TM thermal pastes enhances device reliability, prevents overheating, and extends component lifespan — a proven choice for manufacturers seeking both high cooling efficiency and compliance with quality and safety standards.

See also