Transfer tapes are advanced adhesive materials with very low thickness — typically ranging from 30 to 320 micrometers (µm). Despite their thin profile, they provide strong, durable, and aesthetically clean bonds that remain nearly invisible after application. Their key feature is the uniform adhesive layer, which ensures reliable bonding even for very thin, delicate, or transparent components.

Transfer Tape (without carrier)

Ultra-thin and invisible bonding Without a carrier, the tape creates nearly invisible bonds and is ideal for applications requiring discreet, thin adhesive layers.

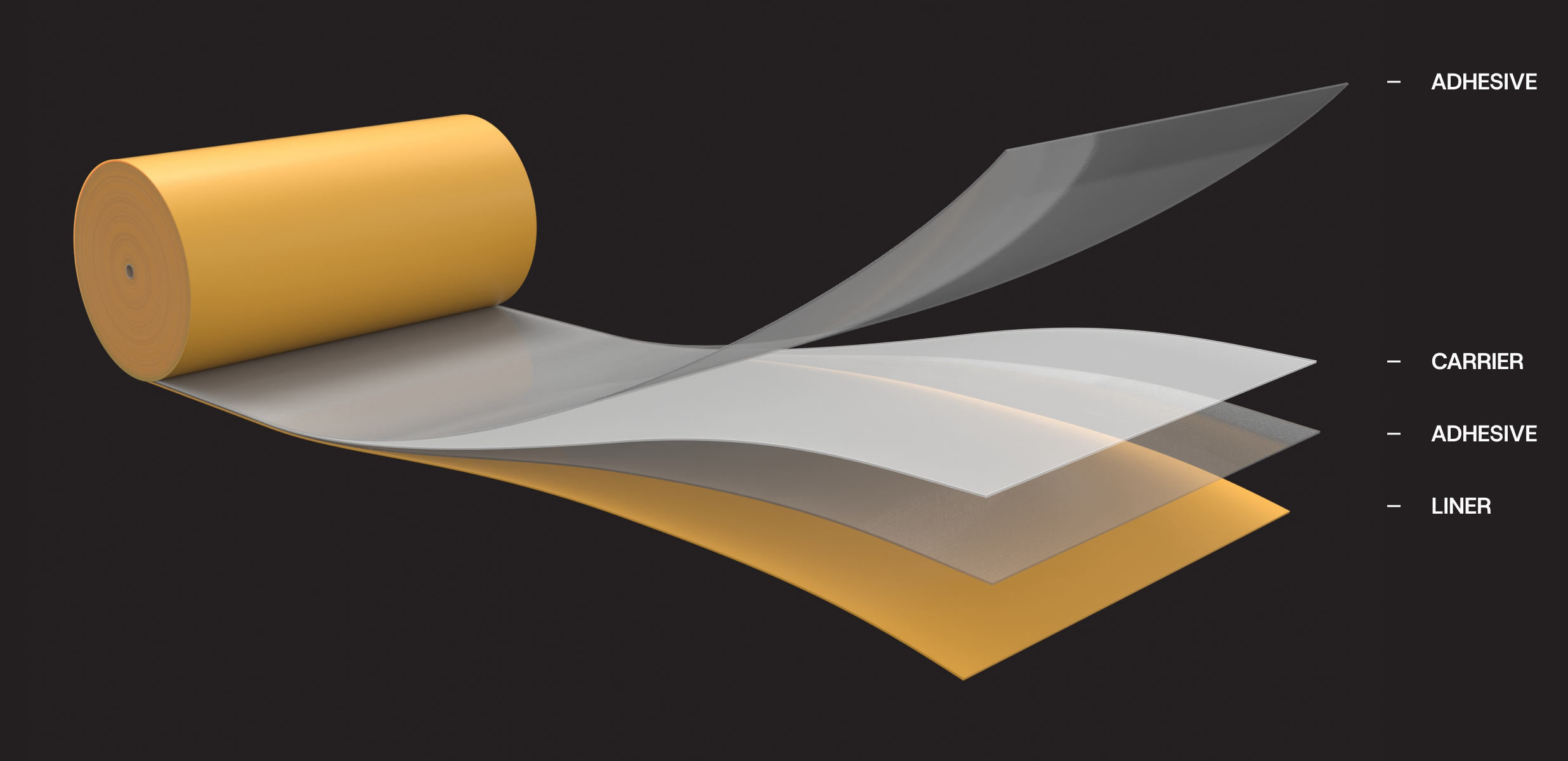

Transfer tape with carrier

Thanks to the presence of a carrier, the tape is more stable during application, which simplifies the process and improves control during cutting and laminating.

Paper as a carrier for transfer tape is lightweight, economical, and easy to convert. It allows precise die-cutting and works well in applications requiring short-term but stable bonding

PVC is a carrier characterized by high flexibility and moisture resistance. It is used in applications where a durable bond and adaptability to uneven surfaces are required.

PET provides dimensional stability and high mechanical strength. It is used in industrial applications that require precision, repeatability, and resistance to loads.

Carrier-free transfer tapes consist of a pure adhesive layer, allowing nearly invisible bonds. They are ideal for aesthetic and thin applications where minimal thickness and joint transparency are essential.

FAQ

Carrier tapes (e.g., PET, PVC, paper) provide greater dimensional stability and easier application in automated processes. Carrier-free tapes are pure adhesive – they offer minimal thickness and an almost invisible bond but require greater precision during application.

The choice of carrier depends on the application conditions: paper is suitable for simple and cost-effective uses, PVC for flexible assemblies, PET for demanding industrial processes, and the carrier-free option for aesthetic and thin applications.

The most important are: adhesive layer thickness, peel adhesion, shear resistance, thermal stability, and compatibility with substrates (LSE, HSE).

Yes, especially versions with carriers (PET, PVC) are designed for automatic applicators. They provide stability, repeatability, and easier handling in production lines.

Yes. Transfer tapes – both with and without carriers – can be supplied in spools tailored to assembly lines. Spooling reduces downtime, minimizes waste, and ensures smooth operation in automated processes, especially in large-scale production.

See also

Transfer tapes are specialized self-adhesive materials that, thanks to their very low thickness (typically ranging from 30 to 320 µm), are widely used across industries. They enable aesthetic and durable bonding of thin elements such as foils, labels, panels, or electronic components. With their uniform adhesive layer, transfer tapes provide high adhesion, stable parameters, and suitability for both manual assembly and automated production lines. This makes them a highly valued solution in industries such as electronics, advertising, automotive, and home appliances.

Transfer tapes without a carrier are ultra-thin adhesive films consisting solely of adhesive. As a result, they create nearly invisible, aesthetic bonds and are indispensable in applications that require maximum discretion and minimal bond-line thickness. They are widely used in the assembly of LCD/OLED displays, protective films, labels, and delicate electronic components. Their key advantage is perfect conformity to micro-irregularities and high transparency, making them a popular choice in projects where appearance and precision are just as important as bonding strength.

Transfer tapes with a carrier (paper, PET, PVC) combine the advantages of a thin adhesive layer with additional mechanical stability. The carrier makes handling easier, improves control in die-cutting and laminating processes, and enhances precision in automated applications. As a result, carrier-based transfer tapes are ideal for industrial sectors where repeatability, efficiency, and resistance to mechanical stress are essential. They are commonly used for mounting control panels, thin structural elements, foil lamination, and the production of technical labels. Their easier handling and high reliability make them the perfect choice for serial and industrial-scale applications.

Siemiradzkiego 46 str.

05 -080 Izabelin, Poland

TAX ID: 7343550873